Precursor Chemicals: The Foundation of Modern Industrial Production

The Role and Significance of Precursor Chemicals

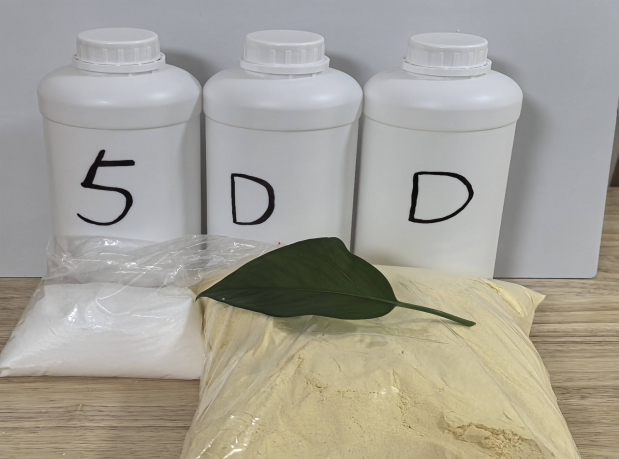

In the complex and highly specialized fields of pharmaceuticals, agrochemicals, and polymers, precursor chemicals play a fundamental and indispensable role in the chemical manufacturing process. These chemicals serve as the basic building blocks, simple yet crucial substances that can be further transformed and combined to create more complex and sophisticated compounds. This article aims to provide a comprehensive exploration of precursor chemicals, delving into their definitions, diverse applications, and the emerging trends that are shaping their production and use across various industries.

Understanding Precursor Chemicals

A precursor chemical can be defined as a transformative substance within a specific industry, undergoing chemical changes to ultimately produce the desired end product. In the pharmaceutical industry, for instance, precursor chemicals are commonly referred to as starting reagents. These starting reagents undergo a series of chemical reactions, often involving multiple steps and complex processes, to transform into active pharmaceutical ingredients (APIs). APIs are the key components of medications, responsible for their therapeutic effects. In the production workflow, it is essential to optimize every aspect of the manufacturing process while maintaining strict quality control and adhering to precise parameters. This ensures that the final products meet both industry - established standards and legal requirements. Given the critical nature of precursor chemicals in these processes, a thorough understanding of their properties, reactivity, and handling is of utmost importance for manufacturers and researchers alike.

The Benefits of Precursor Chemicals in Production

Over the years, the use of precursor chemicals has demonstrated numerous benefits in enhancing industrial production. In various industries, these chemicals have proven to be effective tools for waste management, cost reduction, and output improvement. By carefully selecting and utilizing precursor chemicals, manufacturers can better control the chemical reactions involved in production, minimizing the generation of unwanted by - products and reducing waste. This not only helps in conserving resources but also contributes to a cleaner and more sustainable production environment. Additionally, precursor chemicals can lead to significant cost savings. By streamlining production processes and improving reaction efficiency, companies can reduce raw material consumption, energy usage, and production time, all of which directly impact the bottom line. Moreover, the use of benign synthetic methods, which often rely on precursor chemicals, can enhance production efficiency while promoting a healthier and more sustainable industrial environment. Such methods align with global sustainability goals, making companies more competitive in the market as consumers and regulatory bodies increasingly prioritize environmental responsibility.

Precursor Chemicals in the Renewable Energy Sector

The renewable energy sector has emerged as an important area where precursor chemicals are playing an increasingly significant role. As the world transitions towards greener energy alternatives, there is a growing demand for biofuels and advanced energy storage solutions. Precursor chemicals are essential in the production of these technologies. For biofuels, specific precursor chemicals are used to synthesize the fuels from renewable sources such as plant materials or waste. In the case of energy storage, precursor chemicals are involved in the manufacturing of batteries and other energy - storage devices, enabling the development of more efficient and longer - lasting solutions. This growing application in the renewable energy sector highlights the need for continuous innovation in precursor chemical research. Scientists and manufacturers are constantly working to develop new and improved precursor chemicals that can meet the evolving needs of the renewable energy industry, driving the transition towards a more sustainable energy future.

The Impact of Tightening Environmental Regulations

However, the use of precursor chemicals is not without its challenges. In recent years, environmental regulations regarding precursor chemicals have become increasingly stringent. This presents a significant risk for manufacturers, as ensuring compliance often comes at a cost, either in terms of productivity, increased operational expenses, or both. Stricter regulations mean that companies need to invest more resources in environmental protection measures, safety protocols for handling chemicals, and ethical procurement of raw materials. There is an escalating need for advanced compliance strategies that balance environmental responsibility with production efficiency. Businesses that can successfully integrate sustainability into their operations, especially in the sourcing and manufacturing of precursor chemicals, are more likely to gain a favorable position in the market. They can not only meet regulatory requirements but also attract environmentally conscious consumers and investors, giving them a competitive edge in an increasingly crowded and competitive industry landscape.

The Future of Precursor Chemicals

In conclusion, precursor chemicals are the vital building blocks that underpin the production of countless products across diverse sectors. Their impact on production cycles, encompassing aspects such as efficiency, cost, and environmental footprint, cannot be overstated. In today's highly competitive industrial ecosystem, it is imperative for manufacturers to stay abreast of the latest innovations in precursor chemical production. As sustainability efforts continue to gain momentum, the demand for precursor chemicals is expected to rise significantly. The future of the precursor chemicals industry will be shaped by new applications, innovative synthetic methods, improved production techniques, and strict compliance with regulatory requirements. By embracing these trends and investing in research and development, companies can ensure their long - term success and contribute to a more sustainable and prosperous future for the chemical industry as a whole.

Table of Contents

- Precursor Chemicals: The Foundation of Modern Industrial Production

- The Role and Significance of Precursor Chemicals

- Understanding Precursor Chemicals

- The Benefits of Precursor Chemicals in Production

- Precursor Chemicals in the Renewable Energy Sector

- The Impact of Tightening Environmental Regulations

- The Future of Precursor Chemicals