Understanding Pharmaceutical-Grade Menthol Crystal: USP-NF and FCC Compliance Requirements

What USP-NF and FCC Monographs Specify for Menthol Crystal Purity (99.0%) and Identity

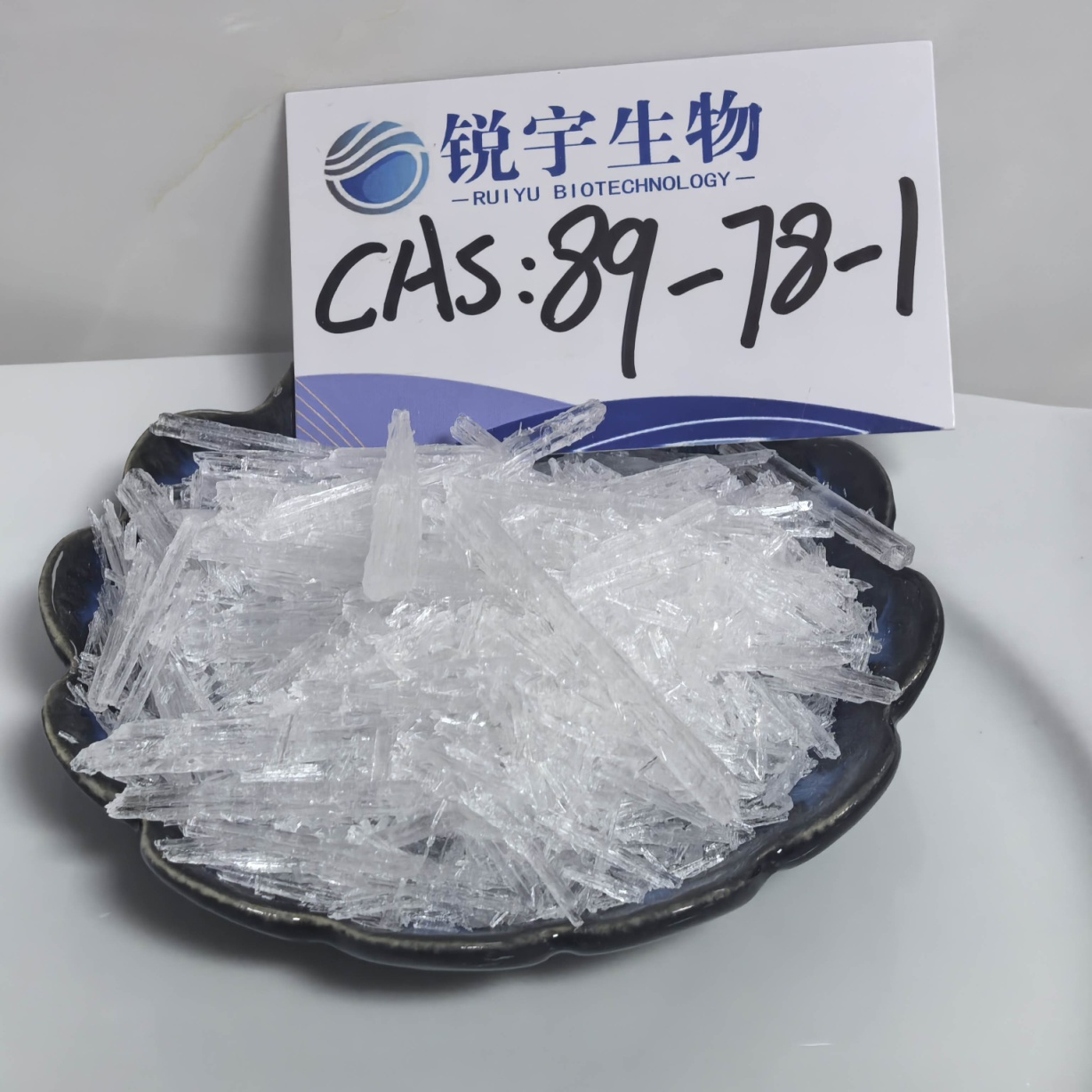

For pharmaceutical grade menthol crystals, there are some pretty strict rules about purity and identity set by organizations like the USP-NF and FCC. These standards basically say the product needs to contain at least 99% L-menthol, which gets checked through something called gas chromatography. To make sure we're actually looking at menthol and not some impostor compound, they run infrared spectroscopy tests comparing samples to known reference materials. There's also a limit on leftover solvents from processing. Hexane, for instance, can't be present above 290 parts per million. When it comes to heavy metals contamination, things get even tighter. Lead levels need to stay below 10 ppm and arsenic under 3 ppm according to USP guidelines. The FCC goes one step further by requiring actual sensory testing where experts sniff and taste samples to ensure they have the right characteristics needed for medicine applications.

Why Chirality (L-Menthol Enantiomeric Excess) Is a Non-Negotiable USP Criterion - Not Just Purity

When it comes to USP standards, we're talking about something much more specific than just basic chemical purity. The requirement actually demands at least 99% enantiomeric excess of L-menthol, which happens to be the form that delivers both the familiar cooling sensation and actual therapeutic benefits. On the flip side, D-menthol doesn't work as intended and might even cause unwanted reactions, so getting that chiral purity right really matters. Most labs rely on chiral chromatography techniques to check these specs, since consistent results from one production batch to another are absolutely vital for proper medication function. Small amounts of wrong enantiomers can mess with how drugs get absorbed and behave in formulations. That's why manufacturers need to focus on stereochemical control rather than just standard assays when following CGMP guidelines for their active pharmaceutical ingredients.

Essential Certifications and Documentation for Validating Menthol Crystal Quality

Certificate of Analysis (CoA) Breakdown: Assay, Residual Solvents, Heavy Metals, and Microbial Limits

A valid Certificate of Analysis (CoA) is indispensable for confirming pharmaceutical-grade status. Each batch-specific CoA must include:

- Assay Purity (99.0%), validated by gas chromatography or HPLC per USP-NF;

- Residual Solvents, tested against ICH Q3C thresholds—for example, acetone and ethanol must remain well below permissible limits;

- Heavy Metals, reported against USP <231> (e.g., lead ≤10 ppm, arsenic ≤3 ppm);

-

Microbial Limits, demonstrating absence of E. coli and total aerobic microbial counts within USP <61> specifications.

All CoAs must document testing dates, analytical methods, instrument calibration records, and authorized quality personnel signatures to ensure full traceability and regulatory defensibility.

SDS/MSDS and GMP Alignment: Why Safety and Manufacturing Documentation Must Support Regulatory Use

Safety Data Sheets (SDS) for pharmaceutical-grade menthol crystal must reflect Good Manufacturing Practice (GMP) alignment—not just hazard communication. A compliant SDS includes:

- Hazard Identification: Flash point (>93°C), dust explosion potential, and safe handling precautions;

- GMP-Relevant Controls: References to cleanroom classification (e.g., ISO Class 7), equipment qualification, environmental monitoring, and personnel training protocols;

-

Transportation Compliance: UN 4.1 classification and packaging certification for flammable solids.

Without GMP-integrated SDS documentation and batch-specific CoAs, manufacturers risk FDA 483 observations or import alerts for insufficient evidence of safety, purity, or process control.

Pharmaceutical-Grade vs. Technical-Grade Menthol Crystal: Key Differentiators That Matter in Formulation

When comparing pharmaceutical grade versus technical grade menthol crystals, what really matters isn't just how pure they look on paper but whether they meet strict regulations, maintain their molecular structure, and work reliably when put to use. For medicines, the stuff needs to pass those USP-NF and FCC standards too. That means at least 99% purity overall and over 99% of the right L-menthol form so it behaves predictably inside the body once taken. Technical grade products usually sit around 90 to 95% purity with mixed isomers though. This works fine for perfumes or manufacturing processes but creates problems when used in actual treatments because formulations might break down unexpectedly, absorption varies unpredictably, and there could be hidden impurities such as traces of heavy metals left behind from production. Getting certified for pharmaceutical use involves detailed documentation tracking every step from raw materials to final product testing for things like leftover solvents below 500 parts per million, microbe levels, and confirmation of correct chirality. These requirements don't apply to technical grade materials at all. If someone tries switching between these different grades without proper testing first, dissolution times in pain relief creams can change dramatically somewhere between 30 to 40 percent, which makes a real difference in how effective the medicine actually is for patients.

Sourcing Reliable Pharmaceutical-Grade Menthol Crystal: Traceability, Ethics, and Supply Chain Integrity

How ISO 22000, ICH Q7, and Ethical Sourcing Practices Reduce Risk in Active Pharmaceutical Ingredient (API) Supply

Getting reliable pharmaceutical grade menthol crystals requires following several international quality standards. The big ones include ISO 22000 which sets food safety rules for the supply chain, and ICH Q7 that specifically addresses current good manufacturing practices for active pharmaceutical ingredients. These standards aren't just paperwork exercises either. They actually require companies to document every step of their processes, manage changes properly when things get tweaked, handle any deviations that occur during production, and qualify all suppliers involved in extraction, crystallization, and final packaging operations. Ethical considerations matter too. Companies need to know exactly where their raw materials come from, like how Mentha arvensis is grown, whether workers are treated fairly throughout the supply chain, and if harvesting methods are sustainable. Third party auditors check these claims regularly. Traceability systems run throughout the entire product journey tracking everything from lot numbers and harvest dates to specific processing parameters and test results. This kind of comprehensive tracking helps prevent bad actors from introducing fake or contaminated materials into the mix. For pharma manufacturers, this whole system works to reduce risks of contamination, maintain consistent product quality batch after batch, and meet regulatory requirements worldwide. At the end of the day, it's all about keeping patients safe and avoiding costly recalls down the line.

FAQs about Pharmaceutical-Grade Menthol Crystal

What ensures the purity of pharmaceutical-grade menthol crystals?

Purity is ensured through adherence to USP-NF and FCC standards, with L-menthol content needing to be at least 99% verified through gas chromatography.

Why is chirality important in menthol crystals?

Chirality is crucial because the L-menthol enantiomer provides therapeutic benefits and the familiar cooling sensation, whereas D-menthol can cause unwanted reactions.

What documentation is necessary for validating menthol crystal quality?

A Certificate of Analysis (CoA), Safety Data Sheets (SDS), and Good Manufacturing Practice (GMP) alignment are necessary for quality validation.

What distinguishes pharmaceutical-grade from technical-grade menthol crystals?

The primary differences include the level of purity, compliance with USP-NF and FCC standards, and documentation requirements, making pharmaceutical-grade suitable for medicinal use.

Table of Contents

- Understanding Pharmaceutical-Grade Menthol Crystal: USP-NF and FCC Compliance Requirements

- Essential Certifications and Documentation for Validating Menthol Crystal Quality

- Pharmaceutical-Grade vs. Technical-Grade Menthol Crystal: Key Differentiators That Matter in Formulation

- Sourcing Reliable Pharmaceutical-Grade Menthol Crystal: Traceability, Ethics, and Supply Chain Integrity

- FAQs about Pharmaceutical-Grade Menthol Crystal