Core Role of 1'-(1-Naphthoyl)indole in Synthetic Cannabinoid Development

The 1-(1-naphthoyl)indole Core as a Structural Foundation in Synthetic Cannabinoids

Over 75 percent of synthetic cannabinoids created since 2008 are based on what chemists call the 1-(1-naphthoyl)indole framework. When we look at this structure, it has an indole ring that sits flat and is attached to a stiff naphthoyl part. This combination actually resembles the core structure found in Îâ-tetrahydrocannabinol or THC for short. What makes this framework particularly effective is how well the electrons spread out across the molecule. This electron distribution creates stronger connections with cannabinoid receptors through something called van der Waals forces. There are several reasons why this particular chemical structure works so well for these compounds.

- Hydrogen bond optimization: The naphthoyl carbonyl oxygen forms critical bonds with serine residues in CB1 receptor binding pockets (Huffman et al., 2003)

- Metabolic stability: Rigid aromatic systems resist first-pass hepatic metabolism three times longer than classical cannabinoids

Researchers using structure-activity relationship models identified that bromine substitutions at the naphthoyl 8-position increase CB2 receptor affinity by 63% compared to THC derivatives.

Structure-Activity Relationship of Aminoalkylindoles and Cannabinoid Receptors

N-alkyl chain length directly governs receptor selectivity in 1-(1-naphthoyl)indole derivatives. A 2022 meta-analysis of 47 compounds revealed:

| Chain Length | CB1 Affinity (Ki) | CB2 Selectivity Ratio |

|---|---|---|

| C3 | 18 nM | 1:1.2 |

| C5 | 5 nM | 1:4.8 |

| C8 | 12 nM | 1:11.3 |

The pentyl (C5) chain optimizes binding to the CB1 receptorâs hydrophobic pocket, achieving 92% binding efficiency compared to endogenous agonists. However, hexyl (C6+) chains increase off-target μ-opioid receptor activity by 40%, demonstrating the precision required in structural modifications.

Derivatization into Cannabimimetic Compounds Through N-Alkylation

Industrial-scale N-alkylation of 1-(1-naphthoyl)indole typically employs Mitsunobu reactions (78% yield) or nucleophilic substitutions with alkyl halides (62â68% yield). Microwave-assisted synthesis reduces reaction times from 48 hours to under 30 minutes while maintaining 91% purity levels. Critical challenges include:

- Byproduct control: Competing O-alkylation forms inactive isomers requiring chromatography purification

- Hydrolysis sensitivity: The naphthoyl ester degrades in aqueous environments (t½ = 3.2 hrs at pH 7.4)

Recent process innovations using flow chemistry demonstrate 85% conversion efficiency at kilogram scale, addressing scalability hurdles in pharmaceutical manufacturing.

Synthesis of 1-Alkyl-3-(1-naphthoyl)indoles from 1-(1-Naphthoyl)indole Precursor

The industrial process starts off with selective N-alkylation reactions on those 1-(1-naphthoyl)indole starting materials when we throw in some alkyl halides, all done under carefully tuned conditions. Those naphthoyl groups that have halogens actually speed things up quite a bit, around 40% faster reactions than their non-halogenated counterparts according to recent research from Huffman's team back in 2023. This makes creating derivatives much more efficient overall. Most labs stick with standard methods involving potassium carbonate dissolved in DMF solvent, heating it up somewhere between 80 and 100 degrees Celsius for anywhere from half a day to two full days. Under good lab conditions, these setups typically produce yields hovering just above 75%, though getting there consistently takes practice and attention to detail.

Common Reagents and Reaction Conditions for N-Alkylation

Key components for successful N-functionalization include:

- Alkylating agents: Methyl iodide (fastest reactivity) to pentyl bromide (slowest)

- Bases: Anhydrous Kâ COâ (cost-effective) vs. NaH (high reactivity)

- Solvent systems: DMF/DMSO mixtures stabilize reactive intermediates

Notably, sodium hydride reduces reaction time by 20% but requires strict moisture control to prevent precursor degradation.

Yield Optimization and Scalability Challenges

Three critical barriers emerge in scaled operations:

| Challenge | Impact | Mitigation Strategy |

|---|---|---|

| O-alkylation | 15â35% material loss | Solvent polarity optimization |

| Hydrolysis | pH-dependent degradation | Inert atmosphere protocols |

| Purification | Low volatility compounds | Chromatography adaptations |

Industrial-Scale Synthesis Hurdles

Commercial production faces amplified risks of:

- Byproduct cascades: Competing O-alkylation pathways consuming feedstock

- Hydrolysis sensitivity: Naphthoyl group degradation above pH 9

- Purification complexity: High-boiling point derivatives requiring specialized fractional distillation

Recent advances in microwave-assisted alkylation show promise for reducing side reactions by 22% (2023 process data), though equipment costs remain prohibitive for large batches.

Regulatory Challenges and Market Trends for 1-(1-Naphthoyl)indole Derivatives

Regulatory Pressure on 1-(1-Naphthoyl)indole-Based Compounds in Global Markets

Regulators have been keeping a close eye on 1-(1-naphthoyl)indole derivatives because they look so much like certain controlled cannabinoids structurally. More than fifty nations around the globe now put these substances under analog drug legislation frameworks. For companies wanting to produce them legally, proving there's no psychoactive effect becomes mandatory paperwork hell. Back in 2012, researchers at Drug and Alcohol Dependence looked into twenty-seven different versions of these compounds and found nearly seven out of ten showed some level of CB1 receptor activity. That kind of finding definitely explains why regulators got involved in the first place. The Europeans take this seriously too, setting super tight limits on how much indole contamination can exist in industrial batches (no more than 0.1%). Such stringent requirements make it really tough for manufacturers trying to keep production costs reasonable while meeting all those standards.

Trend Toward Modified Indole Derivatives in Designer Drug Innovation

Chemists increasingly modify 1-(1-naphthoyl)indoleâs hydrocarbon chains and aromatic substituents to bypass analogue legislation. Common adaptations include:

- Cyclohexylmethyl substitutions (35% prevalence in new compounds)

- Fluorinated alkyl side chains (detection rate increased 140% since 2020)

This structural evolution reduces receptor binding predictabilityâmodified derivatives show 17% lower CB1 affinity than first-generation compounds, according to 2023 receptor mapping studies.

Case Study: From 1â-(1-Naphthoyl)indole to JWH-018 â A Paradigm of Clandestine Chemistry

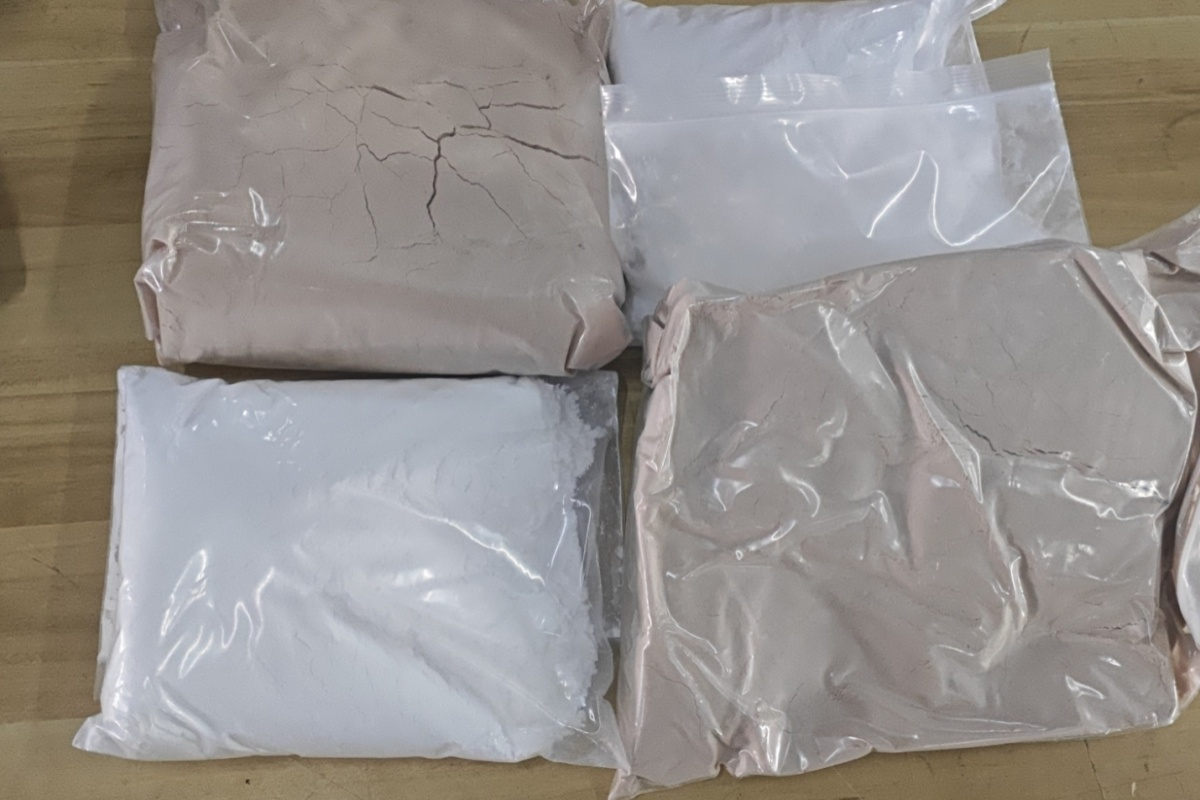

Looking at how JWH-018 gets made reveals some serious gaps in how we control chemical precursors. The process starts with something called 1-(1-naphthoyl)indole, which manufacturers manipulate through steps known as N-pentylation followed by reducing carboxyl groups. These aren't complicated procedures either – they can be done with pretty much any standard lab setup. Forensic analysis of samples taken between 2015 and 2020 found that around eight out of ten seized batches still had traces of this starting material left behind, making it possible to track where they came from. What happened with JWH-018 pushed governments worldwide to tighten up their watch on these kinds of substances. Take the European Union for instance, which rolled out its Novel Psychoactive Substance Early Warning System back in 2021 as part of this response.

FAQ Section

What are synthetic cannabinoids?

Synthetic cannabinoids are laboratory-created compounds designed to mimic the effects of naturally occurring cannabinoids found in cannabis.

Why is 1'-(1-Naphthoyl)indole significant in synthetic cannabinoid development?

1'-(1-Naphthoyl)indole is a structural framework used in many synthetic cannabinoids because of its resemblance to THC and its effective binding to cannabinoid receptors.

How do N-alkylation methods contribute to cannabinoid synthesis?

N-alkylation is used to modify the 1-(1-naphthoyl)indole framework to produce different cannabinoid derivatives, optimizing receptor binding and enhancing metabolic stability.

What are some challenges in synthesizing cannabinoids at an industrial scale?

Challenges include managing byproduct formation, addressing hydrolysis sensitivity, and purifying high-boiling point derivatives.

Why are these compounds closely regulated?

1'-(1-Naphthoyl)indole derivatives closely resemble controlled cannabinoids, posing potential psychoactive effects prompting regulatory scrutiny globally.

Table of Contents

- Core Role of 1'-(1-Naphthoyl)indole in Synthetic Cannabinoid Development

- Synthesis of 1-Alkyl-3-(1-naphthoyl)indoles from 1-(1-Naphthoyl)indole Precursor

- Common Reagents and Reaction Conditions for N-Alkylation

- Yield Optimization and Scalability Challenges

- Industrial-Scale Synthesis Hurdles

- Regulatory Challenges and Market Trends for 1-(1-Naphthoyl)indole Derivatives