Reactivity Risks from Bromine and Alkene Functional Groups

The compound 5-bromo-1-pentene has two parts that make it particularly reactive: one is the bromine atom attached to it, and the other is an alkene group at the end. When these features work together, they create some serious safety concerns. The bromine tends to attract electrons strongly, which makes the whole molecule eager to react with things like amines or even water molecules around it. Not good for stability. Then there's that alkene part, which doesn't have enough electrons itself. This setup allows what chemists call [4+2] cycloaddition reactions just sitting around at room temperature, sometimes leading to unexpected polymer chains forming all on their own. A study from Hebeiruiyu Chemical Research shows that when these kinds of compounds meet oxidizers, trouble follows quickly. Labs working with them need extra precautions because accidents happen fast once those reactions start going.

Thermal Instability and Potential for Decomposition

5-Bromo-1-pentene decomposes above 40°C, releasing toxic hydrogen bromide gas. Prolonged storage—especially in improperly sealed containers—accelerates degradation, with rates rising by 300% due to moisture and oxygen exposure (Safety Science Reports 2023). To maintain stability, store below 25°C and inspect regularly for discoloration, which signals bromine liberation.

Case Studies: Incidents Involving Halogenated Alkenes

- In 2022, residual 5-bromo-1-pentene mixed with dimethyl sulfoxide led to spontaneous ignition, caused by peroxide formation via alkene oxidation.

- An inadequately neutralized 1L spill resulted in chronic respiratory issues among three workers, highlighting the importance of immediate vapor suppression and proper decontamination.

Critical stability thresholds are outlined below:

| Condition | Risk Threshold | Mitigation |

|---|---|---|

| Temperature | >35°C sustained | Refrigerate with inert gas blanket |

| Light exposure | >200 lux for 48 hrs | Use amber glass containers |

| Moisture content | >0.5% H₂O | Add molecular sieves during storage |

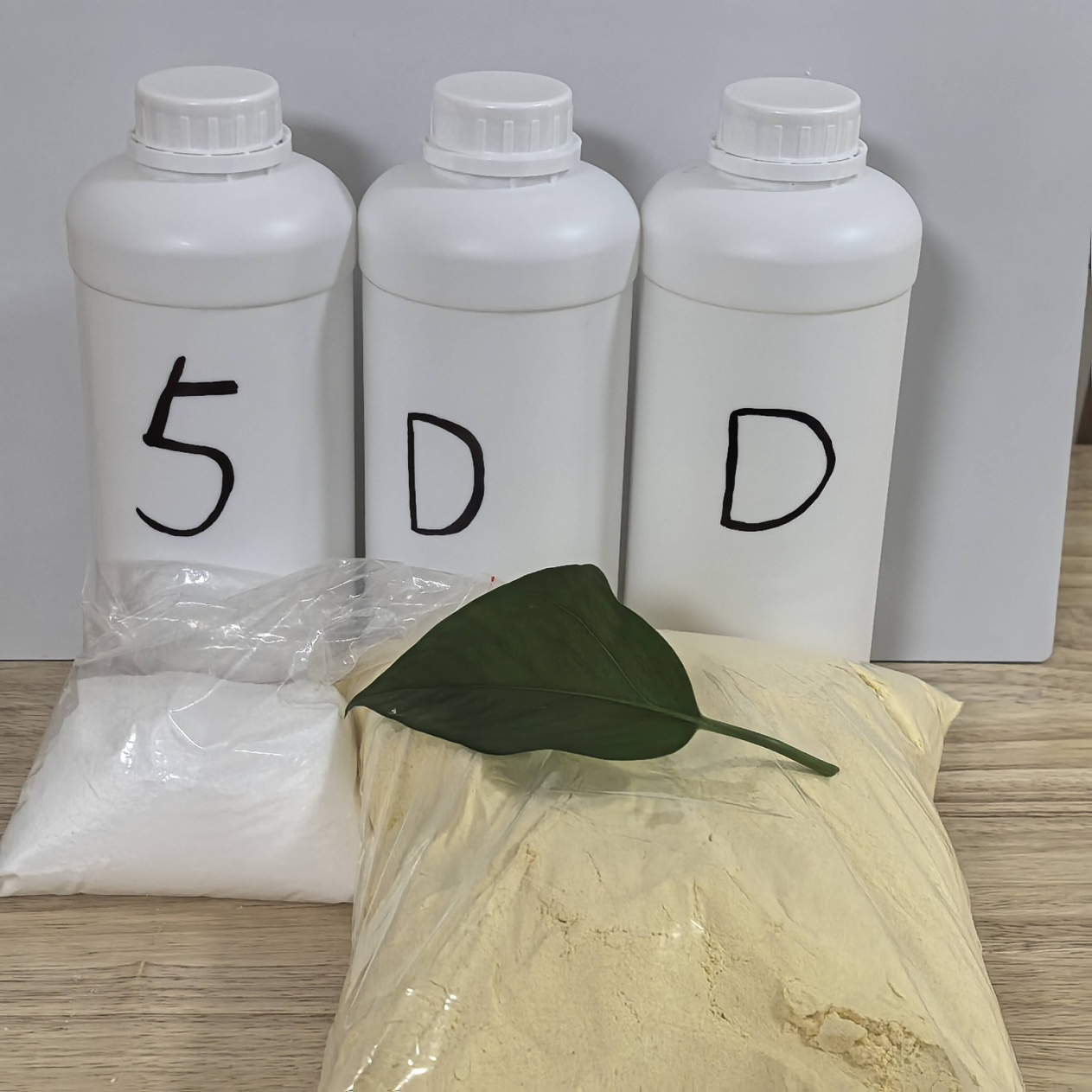

Safe Storage and Handling Conditions for 5-Bromo-1-pentene

Storage under inert atmosphere (nitrogen or argon) to prevent degradation

Storing 5-bromo-1-pentene under nitrogen or argon is essential for preventing unwanted reactions. The inert atmosphere blocks out atmospheric moisture and oxygen that would normally attack both the bromine atoms and the double bond in the molecule. Without protection, these interactions can create dangerous side products such as hydrogen bromide gas. When containers are properly purged before sealing, most labs report maintaining around 95% chemical purity even after 18 months on the shelf. But leave it open to regular air and purity drops dramatically below 70% within similar timeframe, making proper storage absolutely critical for safety and effectiveness.

Refrigerated storage (2–8°C) and protection from temperature fluctuations

Keeping things cool is essential when storing these materials. The ideal range is around 2 to 8 degrees Celsius, so it's best to use those special explosion proof fridges that come with alarm systems for temperature monitoring. Frequent temperature fluctuations should be avoided because they can cause condensation issues and eventually lead to moisture getting into the containers. Research published back in 2022 by the Chemical Stability Quarterly showed something interesting - samples kept refrigerated maintained three times more stability compared to ones left out at normal room temps. For safety reasons, always place them on secondary containment trays. This helps keep them separate from other chemicals that might react badly together, especially stuff like strong oxidizing agents which could create dangerous situations if mixed accidentally.

Use of amber glass containers and PTFE-lined caps to limit light and moisture exposure

Amber glass works really well at stopping UV rays and visible light over 400 nm wavelength, which helps prevent those brominated compounds from breaking down when exposed to light. When it comes to keeping things dry, PTFE lined caps are the way to go. These caps let through less than 0.01% water vapor, making them about 90% better at moisture control compared to regular polyethylene liners that most people use. Don't forget to mark every container with when it was prepared and check them out every three months or so. If managing bigger quantities, keeping storage areas under 3% relative humidity becomes critical since this stops unwanted chemical reactions between molecules called oligomerization from happening.

Personal Protection and Exposure Prevention During 5-Bromo-1-pentene Use

Respiratory Protection Against Inhalation Hazards in Poorly Ventilated Areas

The volatility of 5-bromo-1-pentene means there's real danger if someone breathes it in, especially in places where air doesn't circulate well. Workers handling this stuff need to wear those NIOSH approved masks with special filters for organic vapors that handle halogenated compounds specifically. Labs often forget about proper ventilation during chemical transfers, which explains why according to a recent OSHA report from last year, almost half (that's 42%) of all inhalation incidents happen right during these transfer operations. When the air quality drops below safe levels, meaning anything over 0.1 parts per million of vapor concentration, continuous monitoring becomes absolutely essential to catch dangerous spikes before anyone gets hurt.

Skin and Eye Protection Protocols, Including Emergency Wash Procedures

Direct contact requires comprehensive protective measures:

- Gloves: Butyl rubber (≥ 8 mil thickness), meeting ANSI/ISEA 105-2020 chemical resistance standards

- Eyewear: Tight-sealing goggles compliant with ANSI Z87.1

- Body protection: Chemical-resistant aprons or full-body suits

Emergency response must include readily accessible safety showers (capable of 15-minute flushes) and eye wash stations delivering at least 0.4 gpm, located within 10 seconds of high-risk areas.

Required PPE for Laboratory and Industrial Personnel Handling 5-Bromo-1-pentene

All personnel should wear flame-resistant lab coats, chemical aprons, closed-toe shoes, and appropriate respiratory and eye protection. Mixing operations may generate localized heat up to 65°C (149°F), so face shields are essential. Facilities should enforce PPE inspection checklists aligned with NFPA 704 hazard ratings for brominated compounds.

Engineering Controls: Ventilation and Flammability Management

Managing Flammability Risks in Common Lab and Plant Environments

With a flash point of 18°C (NFPA 2023), 5-bromo-1-pentene presents significant flammability concerns. Maintain vapor concentrations below 10% of the lower explosive limit (LEL) through continuous gas monitoring. Implement secondary containment systems with chemical-resistant liners to contain leaks during transfer.

Effective Ventilation Using Fume Hoods and Vapor Control Systems

Use ducted fume hoods with variable frequency drive (VFD) ventilation systems, which sustain 100–150 fpm face velocity while cutting energy consumption by 40–60% compared to fixed-speed units. Ductless hoods with activated carbon or HEPA filters are not permitted, as adsorption of 5-bromo-1-pentene can lead to peroxide accumulation and explosion risks.

Eliminating Ignition Sources and Controlling Static Discharge

For facilities handling 500 mL or more, implement static control measures including conductive flooring (<1 megaohm resistance), static-dissipative containers, and grounded transfer equipment. Explosion-proof refrigerators are required for cold storage. A 2022 CSB investigation revealed that 78% of incidents involving halogenated alkenes stemmed from ungrounded conductive paths during dispensing.

Emergency Response, Spill Management, and Safety Training

Preparedness is critical when working with highly reactive chemicals like 5-bromo-1-pentene. Comprehensive protocols ensure safe incident response and long-term risk reduction.

Spill Containment, Neutralization, and Decontamination Procedures

When dealing with spills, the first thing to do is get everyone away from the affected area right away. Use stuff like vermiculite that won't react with whatever was spilled to stop it from spreading further. If there are any acidic substances left behind after containment, grab some baking soda solution to neutralize them. Research published last year showed that waiting longer than 15 minutes before cleaning up can actually raise chances of dangerous chemical reactions happening again by around 40% in cases involving certain types of alkene compounds. Safety gear matters too! Everyone involved should be wearing proper protective equipment rated against chemicals while handling this mess. And don't forget about proper disposal either – all contaminated items need to go into those special containers marked with the UN approval stamp.

Chemical Incompatibilities and Safe Waste Disposal Practices

When handling 5-bromo-1-pentene, it's important to keep this substance separate from oxidizers, strong bases, and reactive metals since mixing could lead to dangerous reactions. Waste containers need proper labeling showing exactly what chemicals they contain, and these should be stored in well-ventilated spaces that are kept apart from other materials until they can be disposed of properly. For waste treatment, burning is recommended but must happen at very high temperatures above 1,100 degrees Celsius. This ensures thorough destruction of the compound while reducing the risk of creating harmful brominated dioxins during the process.

Training Programs and Fostering a Strong Safety Culture Around Reactive Chemicals

Studies from Vector Solutions back in 2023 found that when labs run quarterly training sessions following OSHA standards, they cut down on human mistakes by about 62%. What works best? Hands-on practice for spills, knowing how to shut things down during emergencies, and actually looking at those chemical compatibility charts instead of just filing them away. Labs that let staff report close calls anonymously tend to spot problems before they become disasters. Take note: companies that have really solid safety programs see roughly 78% fewer accidents with these tricky halogenated alkene compounds compared to what's normal across the industry. Makes sense when you think about it – people who feel safe are more likely to act safely.

FAQ Section

What are the primary risks associated with 5-Bromo-1-pentene?

The primary risks associated with 5-Bromo-1-pentene are its chemical reactivity due to bromine and alkene groups, as well as its thermal instability which can lead to decomposition and release of toxic gases.

How should 5-Bromo-1-pentene be stored to ensure safety?

It should be stored under an inert atmosphere, with refrigerated storage between 2–8°C, using amber glass containers with PTFE-lined caps to minimize exposure to light and moisture.

What protective measures are recommended for handling 5-Bromo-1-pentene?

Recommended protective measures include wearing NIOSH-approved masks, butyl rubber gloves, tight-sealing goggles, flame-resistant lab coats, and ensuring proper ventilation and emergency wash procedures.

What steps should be taken in case of a spill?

In case of a spill, evacuate the area, contain the spill using non-reactive absorbents like vermiculite, neutralize acidic residues, wear proper protective gear, and ensure proper disposal of contaminated materials.

Table of Contents

- Reactivity Risks from Bromine and Alkene Functional Groups

- Thermal Instability and Potential for Decomposition

- Case Studies: Incidents Involving Halogenated Alkenes

- Safe Storage and Handling Conditions for 5-Bromo-1-pentene

- Personal Protection and Exposure Prevention During 5-Bromo-1-pentene Use

- Engineering Controls: Ventilation and Flammability Management

- Emergency Response, Spill Management, and Safety Training

- FAQ Section