Understanding ADBB and Its Chemical Hazards

Identification of Chemical Hazards Associated with ADBB

Workers handling ADBB (Alkylated Diphenylamine-Based Blend) face serious safety concerns that need immediate attention. The substance is highly flammable with a flash point below 93°C (around 200°F), can explode if combined with strong oxidizers, and has been classified by IARC in 2023 as possibly carcinogenic to humans (Group 2B). Long term exposure poses multiple health risks including respiratory issues, skin irritation after repeated contact, and neurological damage seen in lab animals exposed to levels over 50 parts per million according to NIOSH findings from last year. When assessing risks associated with ADBB, it's important to consider its vapor pressure of 0.12 mmHg at room temperature and its tendency to dissolve in fats (log Kow 4.7). These characteristics mean workers are likely to inhale the chemical and also explain why it sticks around in the environment longer than many other compounds.

Accessing and Interpreting Safety Data Sheets (SDS) for ADBB

The SDS is the primary source for safe handling guidance, with proper use preventing an estimated 92% of chemical incidents (OSHA 2022). Critical sections include:

- Section 2: Hazard identification, including GHS pictograms for flammability, health hazard, and irritation

- Section 8: Exposure controls, specifying an OSHA PEL of 5 mg/m³ (STEL) and the need for continuous air monitoring

- Section 11: Toxicological information, such as an oral LD50 of 1,200 mg/kg in rats, supporting strict PPE requirements

Facilities should verify SDS version dates quarterly, as outdated documentation affects 34% of organizations (Chemical Safety Board 2023). Cross-referencing SDS data with real-time concentration monitoring ensures accurate risk management.

Personal Protective Equipment (PPE) Requirements for Safe ADBB Handling

Selecting Appropriate PPE Based on ADBB's Chemical Properties and Exposure Risk

Choosing the right PPE depends on understanding how volatile ADBB can be, its flammability risks, and how easily it gets absorbed through skin contact. Handling powders regularly requires at minimum NIOSH approved N95 masks plus gloves that meet ASTM D6978 standards for chemicals resistance. Work with liquid forms calls for full coverage Tyvek suits where all seams are taped shut to block those tiny particles down to 0.13 microns in size from getting into the air we breathe. Safety experts generally recommend doing specific job assessments first before deciding if someone needs a powered air purifier system when working continuously over half an hour straight without breaks.

Proper Use, Maintenance, and Inspection of PPE in ADBB Operations

It's important to check respirator seals daily to make sure they're still tight against the face. For gloves, we need to look out for any signs of wear and tear, which means running them through the ASTM F739 permeation test when there's reason to doubt their effectiveness. When it comes to reusable protective gear exposed to ADBB, cleaning with a 10% sodium bicarbonate solution is essential before storing them somewhere clean where they can dry properly without getting contaminated again. During those long bulk transfer operations, multi-layer gloves really start to break down after about two hours work. Tests from Chemical Safety Quarterly back this up showing permeability jumps by around 35% past that mark, so fresh gloves become necessary pretty quickly. Implementing digital tracking for all this stuff makes a big difference too. Facilities that monitor their equipment regularly report seeing equipment failures drop by nearly three quarters compared to places without such systems in place.

Safe Storage, Labeling, and Handling Practices for ADBB

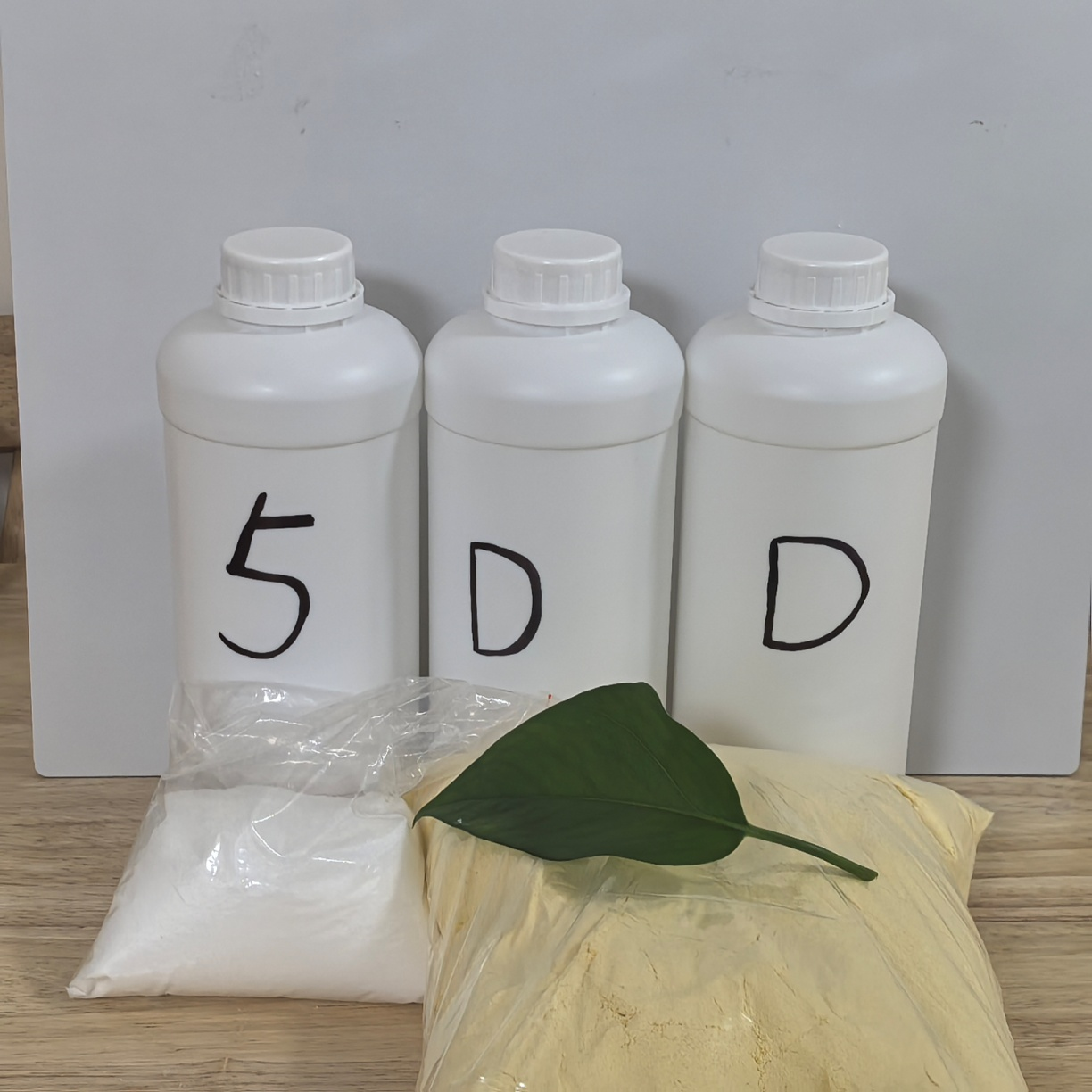

Labeling Chemical Containers and Ensuring Clear Identification of ADBB

Good labeling that lasts through tough conditions plays a big role in keeping chemicals safe. Containers used by ADBB need to show those GHS symbols for hazards, include complete chemical names, plus when they were handled, all printed so they won't wash off easily. Looking at what happens in the field, around one third of chemical incidents actually come down to bad labels or labels that have worn away over time. When it comes to ADBB specifically, the labels really ought to spell out if something catches fire easily or reacts badly with other substances. This helps stop people from combining things that could cause serious problems either while working with them or getting rid of leftovers.

Storing ADBB Safely: Segregation from Incompatible Substances

ADBB needs to stay away from oxidizers, strong acids, and anything that could spark a fire. Fire rated cabinets work well, or better yet, store it in separate containment areas altogether. According to the Chemical Safety Board data from last year, around two thirds of all incidents involving reactive chemicals happen because they were stored together improperly. When working with solvents, keep these substances at least three meters apart from other incompatible stuff. And don't forget about spill control either. The containment system should actually be able to handle more than what's stored there already—something like 110% capacity seems to be the industry standard these days.

Developing Standardized Storage Procedures for ADBB in Shared Facilities

In multi-tenant warehouses, implement access-controlled ADBB storage zones with standardized shelving labels and digital inventory tracking. Essential protocols include:

- Ventilation verification before entry (minimum 4 air changes/hour)

- Color-coded floor markings for designated storage areas

- Monthly inspections of secondary containment integrity

Facilities following these practices saw a 78% reduction in ADBB-related compliance violations in a 2025 regulatory review.

Training, Emergency Response, and Continuous Safety Compliance

Providing Comprehensive Training on ADBB Hazards and Handling Protocols

Workers handling ADBB must receive initial training covering its chemical properties, exposure pathways, and correct PPE use. Instruction should align with SDS guidelines and emphasize thermal decomposition and combustion risks. Hands-on modules in closed-system transfers and spill response help minimize particulate release and reinforce safe practices.

Emergency Planning: Responding to ADBB Spills, Leaks, and Exposure Incidents

Emergency procedures must enable rapid containment, ventilation, and decontamination. Onsite spill kits should contain non-reactive absorbents, and quarterly drills should simulate scenarios like drum leaks or overpressurization events. According to a 2023 OSHA study, workplaces with documented emergency plans reduced incident escalation by 62%.

Maintaining Safety Through Refresher Training and Regulatory Compliance

Annual refresher training keeps personnel informed about updated exposure limits and advances in engineering controls. Regular safety compliance audits help verify adherence to NFPA 704 labeling standards and storage segregation rules. Maintaining detailed training records and corrective action logs supports regulatory due diligence during inspections.

FAQs

What is ADBB?

ADBB refers to Alkylated Diphenylamine-Based Blend, a chemical substance used in various industrial applications but poses significant health and safety risks.

Why is ADBB considered hazardous?

ADBB is highly flammable with a low flashpoint, can explode when combined with oxidizers, and has carcinogenic properties. Long-term exposure can lead to respiratory issues, skin irritation, and neurological damage.

What are the recommended PPE requirements for handling ADBB?

Workers should use NIOSH-approved N95 masks, ASTM D6978-compliant gloves, and full-body Tyvek suits depending on exposure risks. Regular PPE inspections and adherence to safety protocols are critical.

How should ADBB be stored?

ADBB must be stored away from oxidizers and strong acids, ideally in fire-rated cabinets or separate containment areas, with effective spill control measures in place.

What is the importance of Safety Data Sheets (SDS) for handling ADBB?

SDS provides essential information on hazard identification, exposure controls, and toxicological data, helping prevent chemical incidents and ensure safe handling practices.